Tin Free Seel Features

Excellent Paint Adhesion: TFS has excellent paint adhesion proper ties that far surpass those of tinplate, allowing its use for making DRD cans and adhesive bonded cans.

Excellent Heat Resistance: High-temperature baking causes neither discoloration nor deterioration in material proper ties.

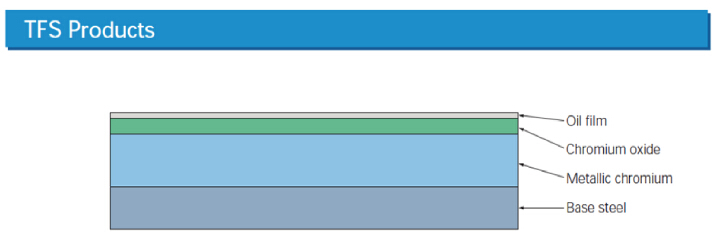

Excellent Resistance to Sulphur Blackening: The metallic chromium in TFS has excellent sulphide resistance property when canning protein-rich foodstuff such as fish. TFS compensates for the expensive sulphur resistant lacquer.

Excellent Filiform Rust Resistance: TFS has an excellent under film corrosion resistance.

Excellent Alkali Resistance: The coating in TFS is not amphoteric. Alkaline products such as detergents and dispersion colours can be packed in TFS with advantage.